Glue XP Hot Melt Padding Machine

EVA Hot Melt Padding Adhesive Application

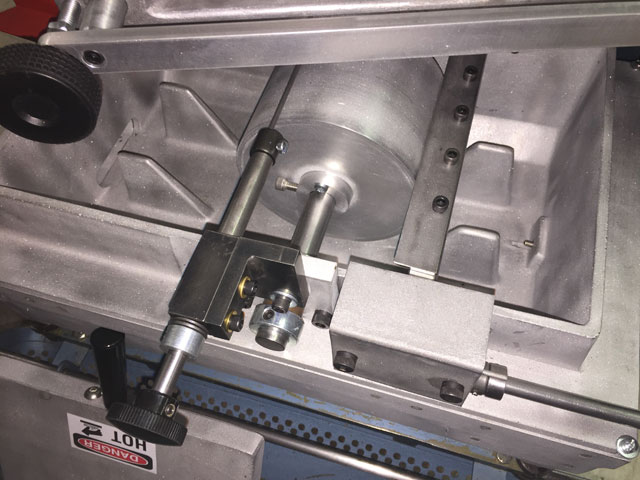

Glue Pot

Aluminum Cast Glue Pot that heats up to 350 F. Hold 8 lbs of Hot Melt Adhesive which takes about 1.5 hours to reach temperature and be fully melted. A wiper rod on the left side of the top of the roller finishes off the wipe for the final thickness of adhesive left on the pad. Typically .010 thick. Its important to have a thinner glue 2500 - 3500 cps to help the wiper clear off the excess back to the tank.

Inner Tank of Glue Pot

The inner tank has a 5-1/4" tall aluminum solid roller that is 3-1/2 inches wide. The heating fins in the tank on the right (2) and left (2) of the roller help heat the glue up quicker. There is a scraper at the 3 o'clock position on the roller which meters the amount of glue on the roller surface. Typically set for 3/32" bead of adhesive.

Glue Pot Roller

When heating the glue pot usually the last place of melting occurs right around the bottom of the roller where the most mass is and the surface of the outer roller. This is why it is important to have a EVA adhesive with a lower melting point of 180 F.

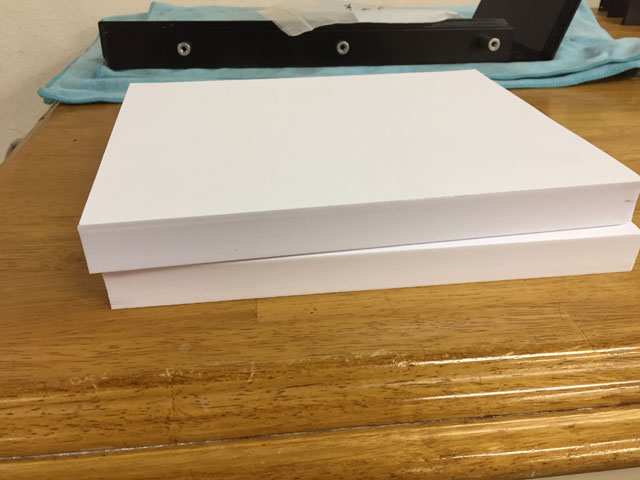

Finished Product

Pads can be made up to fairly large thickness of 1" which requires a large amount of adhesive to cover the surface area. Most company prefer a clear adhesive because of the old standard set by cold gluing which typically dried clear.